As a business owner, you may be facing the challenge of balancing your workforce needs and financial budget.

When it comes to adding resources to your manufacturing assembly process, you have two options: hiring another employee or purchasing a screw driving Cobot.

In this article, we'll discuss the benefits and drawbacks of each option and analyze the costs involved to help you make an informed decision.

Benefits of Hiring Another Employee

- Versatility: An employee can perform a variety of tasks, making them a valuable asset to your business. They can be trained to handle different production processes and can be easily reassigned to another department as needed.

- Interpersonal Skills: Human interaction can play an important role in your production line. Employees can communicate effectively with other team members, provide feedback, and build relationships with suppliers and customers.

- Adaptability: Employees are able to adapt to changes in the production process or new technologies, as they have the ability to learn and grow in their roles.

Cons of Hiring Another Employee

- Cost: Hiring an employee is a significant financial investment. You must consider the cost of salaries, benefits, training, and equipment.

- Training: Employees require time and resources to be trained and get up to speed with your production processes, which can impact your overall production efficiency.

- Turnover: Employees can leave your company, leaving you in the position of having to search for a replacement and starting the training process all over again.

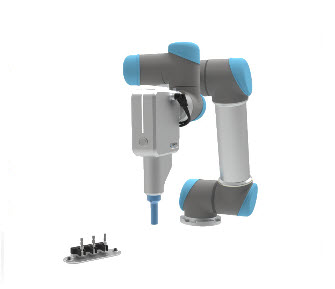

Benefits of Buying a Screw Driving Cobot

- Cost-effective: Cobots are typically less expensive than hiring another employee. You can save on salaries, benefits, and training costs.

- Consistent performance: Cobots are designed to perform tasks consistently and accurately, without taking breaks or getting fatigued.

- Improved production efficiency: Cobots can work around the clock, helping you increase your overall production capacity and reducing the need for overtime pay.

Cons of Buying a Screw Driving Cobot

- Limited capabilities: Cobots can only perform the tasks they are programmed to do and are limited by their hardware and software capabilities.

- Maintenance: Cobots require maintenance and upgrades to keep them operating effectively, which can add to your overall cost.

- Initial Investment: Although Cobots can be cost-effective in the long run, the upfront investment for purchasing and installing a screw driving Cobot can be significant.

Cost Analysis

The cost of hiring an employee will vary depending on their role, salary, and benefits package. On average, you can expect to pay around $50,000 per year for a full-time employee, including benefits.

A screw driving Cobot, on the other hand, will cost anywhere from $35,000 to $75,000, depending on the model and features. However, keep in mind that the initial investment can be offset over time as the Cobot continues to work efficiently, without taking breaks or requiring benefits.

When deciding between hiring an employee or buying a screw driving Cobot, consider your business goals, budget, and production needs. While employees offer versatility and interpersonal skills, Cobots provide consistent performance, cost-effectiveness, and improved production efficiency. A thorough cost analysis will help you make an informed decision that will help you grow your business and meet your production needs. Try our free Cobot ROI Calculator today.

Contact Electromate today to discuss your screw driving Cobot requirement.